CNC Machining is a type of process, which is basically used in the manufacturing sector, in which computers are used for controlling machine tools. CNC machines stand for Computer Numerical Control. These machines are capable of producing the highly accurate and finest, injection molds, piece parts and full-functioning prototypes. Also, it helps to reduce your cost in the long run. These days, almost every manufacturer is using such kind of programmed machines.

How these machines works?

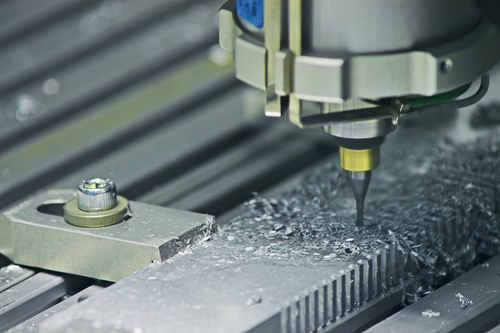

The CNC Machines comprises of a computer, which may look like a normal PC controlling the machines, but actually these machines are programmed Computer Assisted Machining (CAM)/Computer-Aided Design (CAD) software, it means that the machines are using CNC Machining language, which is called G-code, that can control the exact speed and positioning. CNC Machines are used for manufacturing both plastic and metal parts.

Drilling Machine, Lathe, Milling Machines, etc. are some of the machine tools which can run on these CNC Machines. You can also use the machines, which are having multiple axes, as these machines are able to work multi dimensionally for manufacturing high quality parts.

The basic aim of these machines is to remove extra metal, so it will give you proper shape which includes rectangular, round, etc. Otherwise, you have to hire experts for doing this work and they will not be as perfect and as accurate like machines. These machines are ideal for producing those parts where the precision and time level of accuracy is required.

Advantages of CNC Machines

The CNC prototyping machine services are quite recommendable as there is much competition, so it helps to save your time and decreases per unit cost. Following are some other benefits of CNC machines:

- It replaces the manually operated levers or hand wheels.

- It is much easier to manufacture complex shapes, which is quite next to impossible with manual machining.

- Simplicity: the CNC Machines are very simple to use, you only need to learn once that how it works.

- Speed: as the machine is fully automated so the time taken in manufacturing a part is very less, also the whole production is done before the deadline.

- Safety: the whole process is automated, so the operators are out of the work which gives them a much safer environment.

- Accuracy: the machine is totally 100% correct regarding what it produce and the same can be measured in microns for achieving incredible accuracy.

- Repeatability: one a part is manufactured, then the same can be made twice, thrice or more, by using the specifications.

- CNC Machines are flexible as the settings can be changed depending on the project requirement.

Materials used

CNC are capable of manufacturing parts from numerous materials, which includes following materials:

- Nylon

- Aluminum

- Brass

- Plastic

- Copper

- Stainless Steel

- Magnesium

- Steel

- Zinc

CNC prototype machines are worth using and installing as these can be used constantly for 24 hours without any break and are only turned off for maintenance purpose. Always remember to buy them only from reliable sellers.