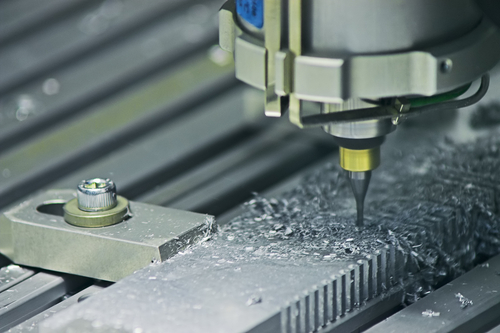

CNC, short form of Computer Numerical Control, has become the firsthand choice of manufacturers for getting machined equipments that have precise specifications and smooth finishing without any further addition to production costs. These machines cut the pieces swiftly and specifically in large numbers to provide planned shapes, sizes and properties.

Don’t worry about finding the companies that provide CNC machining services with timely precision. You can search online. You just have to type CNC machining services China in your search engine’s explore box and the results will give you a lot of names and websites of these companies.

Here are some tips that will help you to find the exact company dealing with CNC machining services appropriate for your type of manufacturing.

Software and Skills

As we all know, before going for any practical action of manufacturing any kind of parts, we need to prepare its design, which is done with the help of software today. This software should be made available by the company you asked for CNC services.

Various softwares for the purpose of machine design are accessible in the market. Your CNC provider will have one or more of them. If you have good knowledge about these softwares, you can choose one that you feel is the best and suitable one for your production and ask the provider to give it to you. The software must provide pointers on your design to help you with the changes, if needed.

Most of the metals and few non-metal materials have found their uses in the manufacturing industry today. Prominent ones are aluminum, iron, titanium, graphite, stainless steel, fiberglass, lexan, etc. Your CNC service provider must have great deal of knowledge and expertise to work on them safely and dynamically.

He should be skilled enough as well as have sufficient amount of quality equipments to provide you with any mechanical and technical support to solve any kind of problem.

Exactitude and Wastage Reduction

All kinds of production have one permanent issue – regular manufacturing.

CNC is the full time solution to this problem. It has the ability to produce accurate and smoothly finished machine parts at a regular time period, that too at a large scale. It turns complex structure into simple manufacturing.

Search for the company that can provide this kind of complex fabrication with the help of software that will not only design 2D, but also 3D components of a machine.

A production tool that produces less and wastes more will only lead your production costs graph upwards instead of bringing it down. CNC will help you in reduction of both, that is, waste and cost.

Additional Services and Facilities

Search for the company that will not only provide you a high quality CNC machine, but also solutions to its problems and other machining processes. These kinds of CNC service providers offer additional services for the convenience of the customer and make the machine more user friendly.

Facilities such as CNC turning, sewing, EDM, hardening, heat treatments, powder coating, etc. are available at reasonable prices. You just have to ask for the citation for the additional services from your provider whenever you are interested in buying them.

A suitable CNC services provider is one who helps its clients to save time, effort and money. At the end, all that matters is quality; so hire a company that can actually promise you a machined product with high class finishing, plus precision.